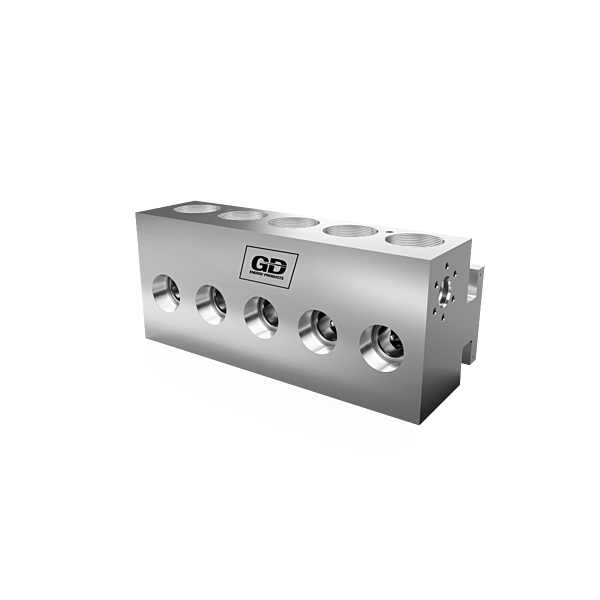

GD Energy Products manufactures high-quality OEM parts and consumables, including industry-leading plungers, available to fit any manufacturers pump. Like all of our consumables, our plungers are manufactured to the same quality standards as our pumps and fluid ends. From machining, to spray & fuse, to finishing, we do it all in house at a facility 100% dedicated to excellence in plunger manufacturing.

GD Energy Products offers both standard and extended life plungers, in all sizes, with strategic stocking in multiple locations to support customers across the globe. GD Energy Products parts and consumables are available in almost every size to fit any fluid end in the market.