Author: Turner Hall, Engineering Manager

The use of hydraulic fracturing has greatly increased throughout shale plays in North America. As the oil and gas industry continues to seek out new products and technologies that will guarantee higher efficiency and cost-savings, GD Energy Products (GDEP) is staying ahead of the curve with new solutions for reliability and extended service life for our line of frac pumps.

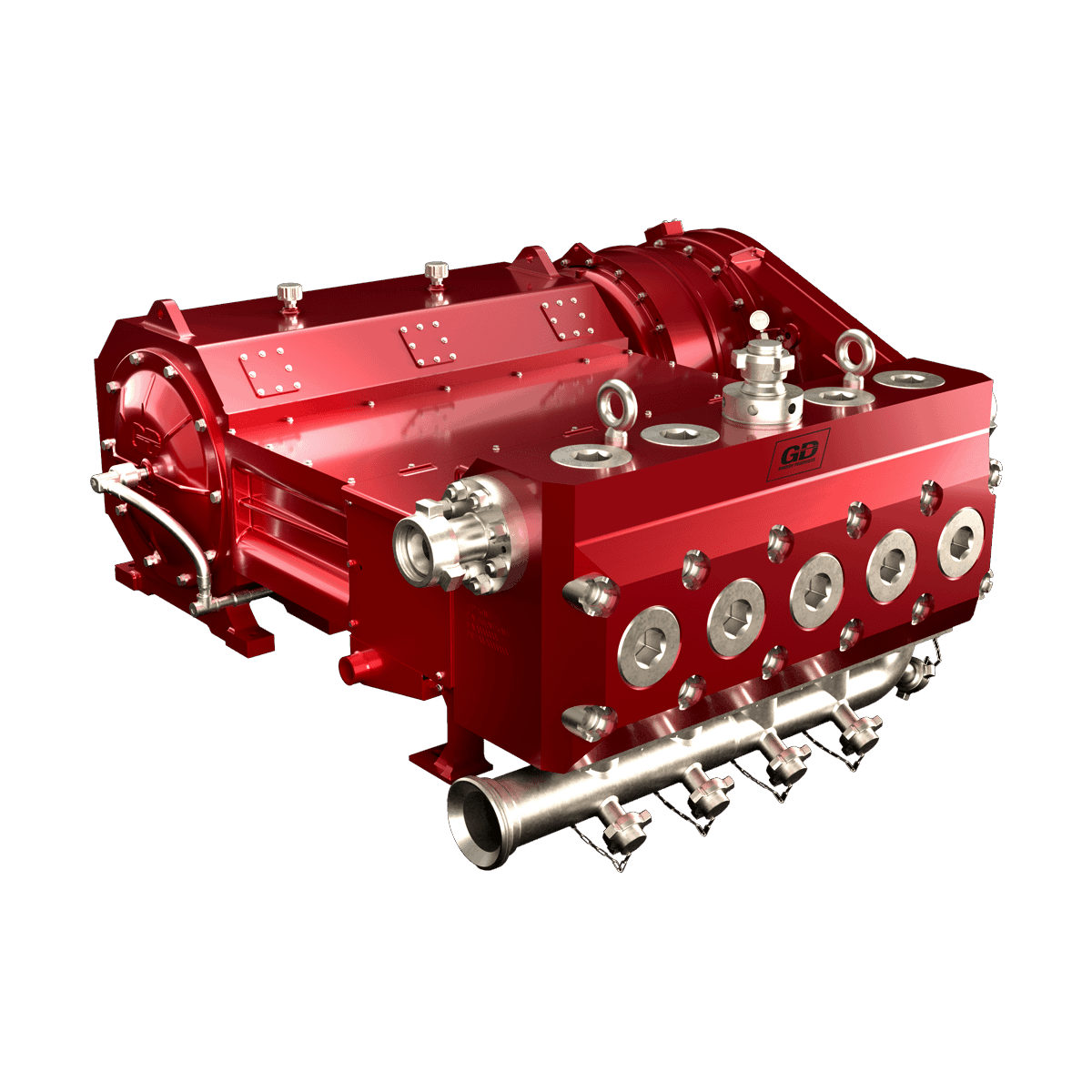

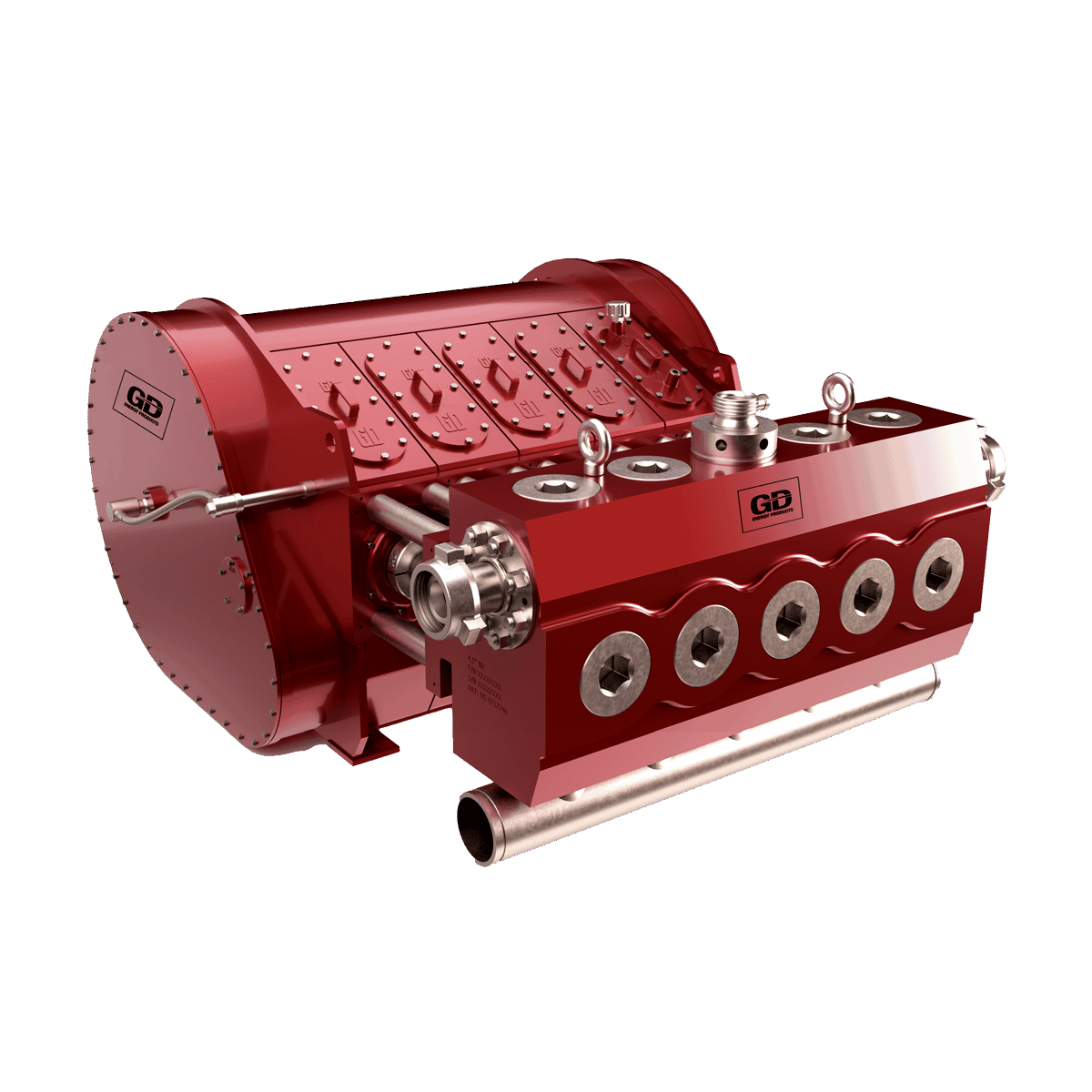

GDEP launched its first 5,000 horsepower (HP) pump, the Thunder 5000 Quintuplex frac pump, in 2019. With its long stroke advantage, our Thunder 5000 can cut the size of a frac spread by 50% compared with a 2500 HP pump. Moreover, with fewer pumps, transmissions and engines to maintain, we can reduce the potential points of failure at the frac site.

However, not all companies are ready to invest in upgrading an entire frac fleet, which is why there is still demand for lower-capacity equipment like our GD 2500Q Heavy Duty Frame (HDF) Quintuplex pump. While GDEP’s 5000 HP exposure is growing, almost 90 percent of pump applications are 2500 HP.

Majority of frac fleets are built around 2500 HP pumps, so redesigns of existing trailers are not necessary. Customers can utilize existing units, while saving significant capital investment. The pumps are not only capable of being powered by diesel engines, but by alternate motors as well. GDEP has 2500 HP pumps running off dual fuel and electric driven motors. Still, longer laterals and more intense frac operations mean that innovation was needed to extend the life of these 2500 HP pumps. In 2021, our company incorporated design elements of the Thunder 5000 into the HDF pump.

The original 2500 HP pumps were designed when the duty cycle was much lower, pumping only 8-12 hours per day. Now, most companies are looking to have 20 hours of uptime or more on their frac jobs each day--these pumps are being run a lot harder and for longer durations of time.

While the 5000 HP pump was designed from scratch and requires the installation of a larger frac trailer, we wanted to offer its customers cost savings benefits by retrofitting the 2500 HDF onto existing trailers and eliminating the need to purchase new trailers.

When redesigning the frame, one of the key design inputs was for it to be a drop-in replacement on the current 2500 HP pump. When comparing the two pumps – the original 2500 HP and the HDF frame – from a distance, they appear to be the same design.

During construction of the HDF frame, GDEP strategically added thicker material to allow for larger welds. This thicker material, utilizing the same steel used in the previous design, made it easier to handle the fatigue damage that is prominent in certain areas. The challenge in designing the HDF frame for the 2500 HP pump was to ensure that the added thickness of the various redesigned plates did not add to the physical size of the pump itself.

Based on our valued customers’ input, the new design elements for the 2500 HP HDF pumps have seen an average service life of over 9,000 hours compared to the older 2500 HP pumps that commonly came back to the shop with frame-related issues after running for approximately 2,000 to 3,000 hours.

Our company has put tremendous work in redesigning the 2500 HP pumps and has seen success in the field without any frames returning from service. With its commitment to service quality, GDEP is dedicated to ensuring the legacy of its pumps continues to advance along with the changes in the industry.

Learn More